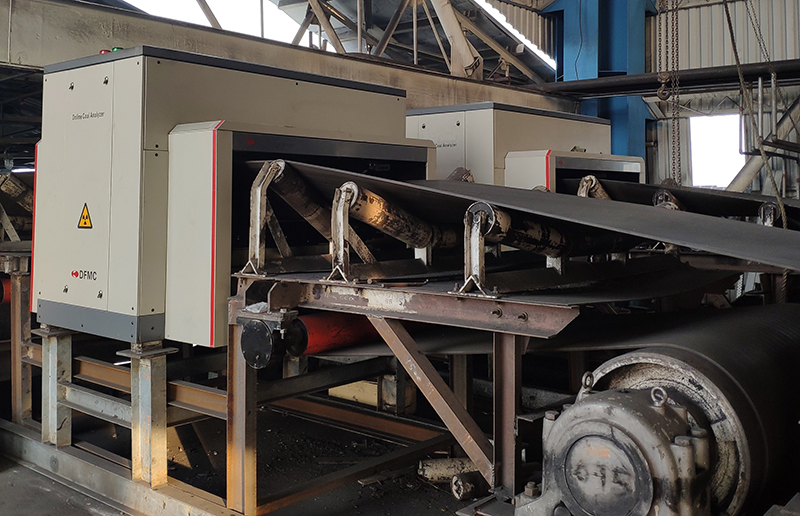

Online Chemical Elemental Analyzer on Conveyor Belt

Product Description

Online Chemical Elemental Analyzer on Conveyor Belt

Single Channel Analyzer on-belt ash-in-coal data for real-time control of plant operations. Recent advances in technology pioneered have significantly improved the performance of dual energy Ash Analyser.

Ash consists mainly of oxides of metallic elements like Si, Fe, Al and Ca. Multi-Channel Element Analyzer Measures the combined total of these elements present in the coal, and this correlates directly to the total Ash.

Two radioactive sources are used:

Am-241: low energy gamma radiation. Absorption of Am-241 gamma rays selectively occurs due to the presence of the major ash-forming elements (Si, Fe, Al, Ca) and the bed depth of the coal.

Cs-137 : high energy gamma radiation. Absorption of Cs-137 gamma rays will be due only to the bed depth of the coal. This allows the Am-241 measurement to be normalised for bed depth. The normalised Am-241 absorption is then correlated to total Ash Analyzer For Cement content by calibrating against laboratory reported ash sample results.

Product Features

■ Comprehensive: Detects all passing materials, quite representative.

■ Fast: Provides analysis data per minute.

■ Effectivity: Provides key parameter data for production in order to conduct effective control.

■ Stable: Double loop temperature control, automatic spectrum stabilization, long-term stable operation.

The prime advantages with DFMC and its product as compared to others are

■ In house resourceful R & D team dedicated to constant development & up gradation.

■ An extended service network & professional service team with hundreds of engineers to provide E&C services, after sales services etc.

■ All key components that determine the performance of the online analyzer are imported from international reputed manufacturers.

■ Applies optimized software algorithm to have stronger on-site adaptability which has more advantages in quality control and operation management of central control personnel.

■ Utmost commitment to minimize stray radiations - radiation protection of the device is designed in strict accordance with the International standard (IAEA), using materials with strong radiation absorption capacity, thick body protection which makes the instrument safer and more reliable to use.

■ DFMC has nearly two decades of experience in the development and protection of industrial nuclear testing instruments.

■ The company has national radiation safety qualification certificate.

■ The service is comprehensive, timely and effective. Lifetime technical services and software free upgrades will be provided to customer.

Successful Case: a power plant in India

An Indian company initially purchased 12 sets of EA-COAL through a single contract in 2017. All these analyzers are used for coal quality testing of burning coal. Online detection of coal quality data can be used to guide coal blending process. In the control room, the operator can adjust the coal blending ratio of different grades of coal through the coal quality information displayed by the instrument, in order to ensure the quality stability & optimize boiler feeding. It helps to reduce the cost of coal burning, excels the automation level of the power plant and eventually helps to improve boiler performance and also minimizes its maintenance. In view of the good effect, the company has placed order for six sets more EA-COAL successively.

DFMC EA-COAL Specifications

Physical Parameters Belt Width 650mm 800mm 1000mm 1200mm 1400mm 1600mm 1800mm 2000mm Other sizes Length 2200mm 2200mm 2200mm 2200mm 2200mm 2100mm 2100mm 2100mm Customization Width 1900mm 1900mm 1900mm 2100mm 2100mm 2300mm 2500mm 2700mm Customization Height 1600mm 1600mm 1600mm 1650mm 1650mm 1700mm 1750mm 1800mm Customization Weight 2800kg 2800kg 2800kg 3000kg 3100kg 3300kg 3500kg 3700kg Customization Bracket Angle 30°~45° Electron Device Signal Processing Cabinet Length=1100mm Width=770mm Height=300mm Signal Processing Cabinet Protection Level IP65 Power 220VAC±10%, 50HZ±5%, 10A, 3-line (L, N, GND) Environment Operating Temperature -30°C~50°C Analysis Principle Prompt Gamma Neutron Activation Analysis (PGNAA) Neutron Source Cf-252 neutron source or a pulsed neutron generator Measurement Parameters Ash, moisture, volatile matter, sulfur content, SiO2, Al2O3, Fe2O3, CaO, TiO2, Na2O, K2O, C, H, O, etc. Calculation Parameters Calorific value, ash melting temperature, volatile matter, H and any possible parameters can apply empirical equation Analysis Time 1 minute, configurable Communications Protocol OPC, network service Signal Processing Cabinet to Host (customer provides) optical fiber, special requirements depend on distance

Application

1. Classified Stacking

EA-COAL system can be used in combination with the process Integrated Control System to classify and stack the raw coal & incoming coal to plant. For the coal washing plant, the coal with high calorific value can be sorted out to maximize the output of high-quality coal; for the power plant and coal chemical industry, the coal can be classified and stacked according to the quality, which is conducive to the subsequent stable coal blending.

2. Coal Blending

EA-COAL system can be used in combination with the automatic proportioning system to optimize the process control of coal blending. The weighing scale and analyzer keeps on sending current analyzed results to the batching system on continuous basis. According to the target value of the user's quality control parameters (calorific value, sulfur content, ash content, and volatile matter, etc.), the batching system will give the optimized formula, and control the amount of feed for each raw material feeder in real-time to make the batching meet the quality control requirements. The batching system can also use manual mode to dispatch the feed quantity of each coal source through intercom system or other ways to guide coal blending.

Picture 5-2 EA-COAL Coal Blending Application

Product Categories : Elemental Analyzer